The Art of Diamond Perfection

In order to produce a unique piece, the very initial step is to create a design.

Mould making is an integral part of the production process. It helps in creating multiple pieces of jewellery of the same design.

Once a design is conceptualized in the mind of the jewellery designer, it is drawn on paper and then into the system.

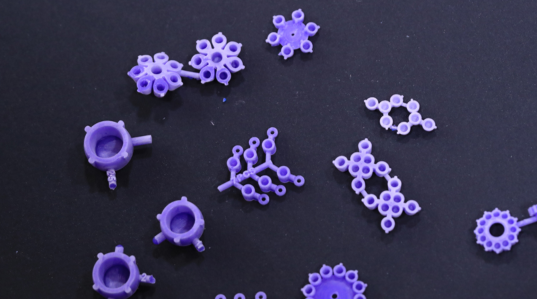

The process of soldering the wax pieces on a wax stem is called “treeing”. A sprue is attached to each piece which in turn is attached with the stem.

Once the CAD design file is ready, it is transferred on 3D Rapid Prototype system. The resin model is created using 3D Rapid Prototyping system (RPT) which is fully functional.

Casting is a very complex process and requires utmost skilled and experienced casters, karigars and master craftsman for the desired final product.

Once the raw casting is clipped off from the casting tree, it has a tiny nub leftover at a place where the gold piece was attached to the sprue.

Stone setting is the art of securely setting or attaching gemstone in the jewellery. Different types of setting are used to create varied designs

Filing is a technique that helps in removing excess metal or solder from a piece that is being worked on

This is the final polish of the piece of jewellery. In polishing, the idea is to add shine to the entire piece of jewellery.

Jewellery pieces with diamonds require pre polishing before the diamonds are set.

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria.

WhatsApp us